ایر موتور (موتورهای پنوماتیکی)

Category : پنوماتیک

ایرموتور های صنعتی، راه حل هایی ایده آل برای بسیاری از صنایع می باشند که از مزایای ایر موتور ها می توان به وزن سبک، حجم کم و … اشاره نمود.

ایر موتور از لحاظ جهت چرخش در دو نوع یک جهته (راست گرد) و دو جهته (چپ گرد راست گرد). با قابلیت تغییر جهت و با قدرت های 100 تا 800 وات تولید می گردند. از جمله کاربرد های ایر موتور می توان. به صنعت ماشین سازی، مخلوط کردن مایعات و محلول ها، حرکت، سوراخکاری، فرزکاری، سنگ زنی و برشکاری اشاره نمود. همچنین قابلیت اتصال بر روی ماشین های ابزار، کمربند های کانوایر Conveyor و وسایل دیگر را دارند.

برای انتخاب نوع آن ها می بایستی به نقطه کاری مشخص شده توسط نمودار، که خود از پارامترهای نشان دهنده سرعت چرخش موتور تحت بار و گشتاور مورد نیاز تشکیل شده است. مراجعه نمود و از طریق آن نمودار ، Air Motor مناسب را انتخاب نمود.

انواع آن ها از لحاظ نوع شفت shaft به سه نوع با شفت خروجی صیقلی، با شفت خروجی رزوه شده و با شفت کولت دار و از لحاظ نوع جهت چرخش همانگونه که در بالا ذکر شد. ایرموتور به دو نوع یک جهته و دو جهته تقسیم بندی می گردند.

ایرموتورها

فروش و تولید و واردات انواع ایر موتورهای ( موتور بادی موتور پنوماتیکی ) دستگاههای معدنی و صنعتی جهت وینچ ها و لودرهای تونلی و دستگاههای حفاری دریل واگن و مغزه گیر.

انواع موتورهای پنوماتیکی روسی -اروپایی ( امکو – اطلس کوپکو و …)

موتورهای 4 – 5 و 6 پیستون و موتورهای پره ای.

انواع موتور بادی یا ایرموتور پنوماتیکی ایر موتور اطلس کوپکو سوئد اینگرسولرند 9000rpm موتور پنوماتیکی. موتور بادی یا ایرموتور با دورهای مختلف دور بالا و انواع قدرت تا ٤ اسب بخار پنوماتیک ایرموتور موتورپنوماتیکی موتوربادی اینگرسولرند آمریکا. ایرموتور اطلس کوپکو سوئد روتاری اکتوشر اکتیویتر اس ام سی ژاپن ایر موتور.

Air motor Atlas Copco With. power outputs from 0.1-6.5 kW, our pneumatic motors are compact and. reliable with high power-to-weight ratios. Sweden air motor Atlas Copco With. power outputs from 0.1-6.5 kW., our pneumatic motors are compact and reliable with high power-to-weight ratios.

HPRco

Sweden ZL05 SMC japan activator rotary activator GAST Gast air motor CompAir INGERSOLLRND MRV. 015 RV -7A ZL05 MDSUB CDRBUWU AirMotor INGERSOLLRND USA MRV 015 AUF Select sm6ama globe airmotors b.v. CE VA4 j&X12 Netherlands benelux nl now.

A pneumatic motor (air motor), or. compressed air engine., is a type of motor which does mechanical work by expanding compressed air. Pneumatic motors generally convert the compressed air energy to mechanical work through either linear or rotary motion.

Linear motion can come from either a diaphragm or piston actuator, while rotary motion is supplied. by either a vane type. air motor, piston air motor, air turbine or gear type motor.

Pneumatic motors have existed in many. forms over the past two. centuries, ranging in size from hand-held motors to. engines of up to several hundred horsepower. Some types rely on pistons and cylinders; others on slotted rotors with vanes (vane motors) and others use turbines. Many compressed air engines improve their performance by heating the incoming air or the engine itself.

Pneumatic motors have found widespread success in the hand-held tool industry,. but are also used stationary in. a wide range of industrial applications. Continual attempts are being made to expand their use to the transportation industry. However, pneumatic motors must overcome inefficiencies before being seen as a viable option in the transportation industry.

Linear

In order to achieve linear motion from compressed air, a system of pistons is most commonly used. The compressed air is fed into an air-tight chamber that houses the shaft of the piston. Also inside this chamber a spring is coiled around the shaft of the piston in. order to hold the. chamber completely open when air is not being pumped into the chamber.

As air is fed into the chamber the force on the piston shaft begins to overcome the. force being exerted on the spring. As more air is fed into the chamber, the pressure increases and the piston begins to move down the chamber. When it reaches its maximum length the air pressure is released from the chamber and the spring completes. the cycle by closing off. the chamber to return to its original position.

Piston motors are the most commonly used in hydraulic systems. Essentially, piston motors are the same as hydraulic motors except they are used to convert hydraulic energy into mechanical energy.

Piston motors are often used in series of two, three, four, five, or. six cylinders that are enclosed in a housing. This allows for more power to be delivered by the. pistons because. several motors are in sync with each other at certain times of their cycle.

The practical mechanical efficiencies attained by a piston air motor are between 40%-50%. GLOBE airmotors b.v. CE model VA4 J&X12 Serie nr. 40120369 +31 172 426 608 www.globe-benelux.nl Netherlands. 120369 ex JF6 7m3 AM410 4am-nrv-22b. 6AM NRV 58 1299GAST MFG CORP. BENTON HARBOR MI U.S.A.

Rotary vane motors

A type of pneumatic motor, known as a rotary vane motor, uses air to produce rotational motion to a shaft. The rotating element is a slotted rotor which is mounted on a drive shaft. Each slot of the rotor is fitted with a freely sliding rectangular vane. The vanes are extended to the housing walls using springs, cam action, or air pressure, depending on the motor design.

Air is pumped through the motor input which pushes on the vanes creating the rotational motion of the central shaft. Rotation speeds can vary between 100 and 25,000 rpm depending. on. several factors which include the amount of air pressure at the motor inlet and the diameter of the housing.

One application for vane-type air motors is to start large industrial diesel or natural gas engines. Stored energy in the form of compressed air, nitrogen or natural gas enters the sealed motor chamber. and. exerts pressure against the vanes of a rotor. This causes the rotor to turn at high speed.

Because the engine flywheel requires a great deal of torque to start the engine, reduction gears are used. Reduction gears create high torque levels with the lower amounts of energy input. These reduction gears allow for sufficient torque to be generated by the engine. flywheel while it is engaged by the pinion gear of the air motor or air starter. The practical efficiency of a vane motor was demonstrated to be 70%.

Turbine motors

Air turbines spin the burr in high-speed dental headpieces, at speeds over 180,000 rpm, but with limited torque. A turbine is small enough to fit in the tip of a hand-piece without adding to the weight. Oil AD220 1 quart 0.94 litres Repair kit K202 Single Rotation Reversible CW CCW 4 Vanes Net wt. 6 lbs (2,7 kg) II 2 GD c T4 Filter AH 103 F. Regulator AH 104 R Gauge AA806 Lubricator AH 105 L Muffler AG600 – above 1,000 rpm. Metal muffler AC990 adds 2″ height when installed. 2AM-NCC-16 AM GAST.

شرکت دانش بنیان برای طراحی و ساخت ایر موتور های صنعتی با کیفیت بالا و عملکرد قابل رقابت با برندهای جهانی. گشتاور و سرعت قابل تنظیم. type b and type c 5.5 کیلووات 3000 دور آر پی ام 3kw.

Application

A widespread application of pneumatic motors is in hand-held tools. impact wrenches, pulse tools, screwdrivers. nut runners, drills, grinders, sanders and so on. Pneumatic motors are also used stationary in a wide range of industrial applications. Though overall energy efficiency of pneumatic tools is low and they require access to. a compressed-air source. there are several advantages over electric tools.

They offer greater power density (a smaller pneumatic motor can provide the same amount of power as a larger electric motor)., do not require an auxiliary speed controller (adding to its compactness). generate less heat, and can be used in more volatile atmospheres as they do not require electric power and do not create sparks. They can be loaded to stop with full torque without damages.

Historically, many individuals have tried to apply pneumatic motors to the transportation industry. Guy Negre, CEO and founder of Zero Pollution Motors, has pioneered this field since the late 1980s. Recently Engine-air has also developed a rotary motor for use in automobiles. Engine air places the motor immediately beside the wheel of the vehicle and uses no intermediate parts. to transmit motion which means almost all of the motor’s energy is used to rotate the wheel.

History in transportation

The pneumatic motor was first applied to the field of transportation in the mid-19th century. Though little is known about the first recorded compressed-air vehicle, it is said that. the Frenchmen Andraud and Tessie of Moray ran a car powered by. a pneumatic motor on a test track in Chaillot, France, on July 9, 1840. Although the car test was reported to have been successful, the pair didn’t explore further expansion of the design.

The first successful application of the pneumatic motor in transportation was the Mekarski system air engine used in locomotives. Mekarski’s innovative engine overcame cooling that accompanies air expansion by heating air in a small boiler prior to use.

The Tramway de Nantes, located in Nantes, France, was noted for. being the first to use Mekarski engines to power their fleet of locomotives. The tramway began operation on. December 13, 1879, and continues to operate today, although the pneumatic trams were. replaced in 1917 by more efficient and modern electrical trams.

هیدرولیک پنوماتیک ابزار دقیق ایرموتور وکیوم

American Charles Hodges also found success with pneumatic motors in the locomotive industry. In 1911 he designed a pneumatic locomotive and sold the patent to the H.K. Porter Company in Pittsburgh for use in coal mines. Because pneumatic motors do not use combustion they were a much safer option in the coal industry. Many companies claim to be developing compressed air cars, but none are actually available for purchase or even independent testing.

atlas copco made in sweden lzb33 ar004 b876002 r/min 385 7bar 100 psi. ingersollrand model 3rlm2d5/vsm-5357 rpm. 4AM NRV 1100 ser no arf10023 vsm 5369. mod 3840p sp11b30160n rpm 440 3800m.

compair broomwade comp air broom wade 120 lbf/in2 bar max. pressure 8HGAS30CM 2121114 3250 RPM CHECK SPEED FREQUENTLY ENGLAND. SIZE 4840S ARM10011 RPM 255.

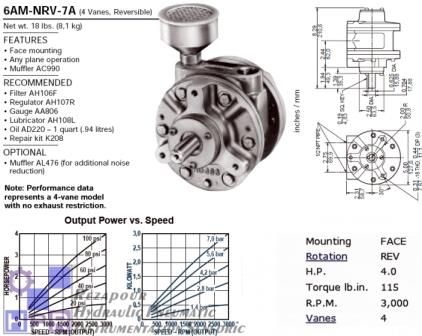

GAST STD133 6AM-NRV-7A 4 VANES REVERSIBLE H.P. 4.0 TORQUE LB.IN. 115 3000 R.P.M. USA U.S.A. globe v10 4AM 6AM 8AM am gastmfg benton harbor mich. MFG. CROP. V4 2.1 KW 2.8 HP DIMENSIONS V4N.M. GLOBE AIRMOTORS V10 9.5KW 12.8HP V8620 N NM MRV va4c globe benelux vane-air-motors VA8C.